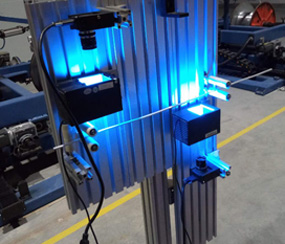

Conductor surface defect visual detection system

The system is mainly used to detect the realtime surface defect on copper and aluminum rectangular wire during the production of continuous extrusion machine, which guarantees the magnetic wire quality in front process.

1. Can detect visually the blister, spur, lump, hole and scratch defect on the surface

2. System includes either 2 cameras to detect bottom and top or 4 cameras on four sides

3. System has its AI deep learning function, which can perfectly remove the error report caused by water and oil stain

4. Detect precision at 0.1mm, which can be further improved by upgrading camera hardware

5. Software setting is easy and convenient to operators

6. Can automatically save defect picture, compile the quantity and possibly analyze offline